High Speed Hydraulic Die-Cutting Machine

- The HS Series High-Speed Hydraulic System Increases Cutting Speed.

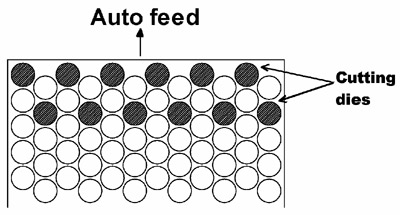

The High speed hydraulic cutting press will achieve 100 cuts per minute for 10mm cutting stroke and 20mm feeding distance to maximize your productivity. - Accurate Servo motor position system saves up to 20% material cost.

Servo motor positioning system maintains positioning accuracy ±0.1mm which can result in up to 20% savings in material cost. - The HS series machine reduces cutting die wear.

The HS machine' extremely robust construction maintains parallelism ensuring high precision punching accuracy which means reduces wear on the cutting dies. - The HS series machine is easy to operate.

Touch-screen monitor with operator/machine dialogue makes user-friendly operation and self-diagnostics trouble shooting.

Interlocked Safety guards with safety circuit to make sure operator in totally safe operation environment.

Range Of Application:

- Thin plastic film from 0.02mm, such as LCD、PC、PS、PP、PET、PVC, etc.

- Thick foams for electronic, rubber, automotive and packaging industries.

- Textiles.

- Non-woven felt.

- Pressure sensitive materials.

- Gasket materials.

- Abrasives.

Advisable die layouts with material auto feed can achieve much more yielding output than conventional cutting method and lead to good material saving.

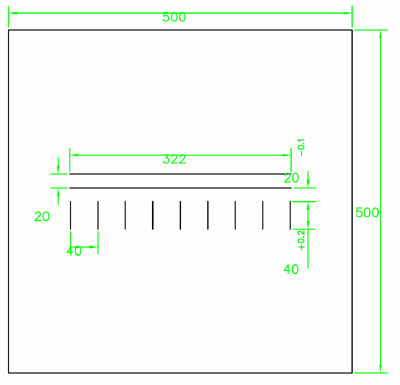

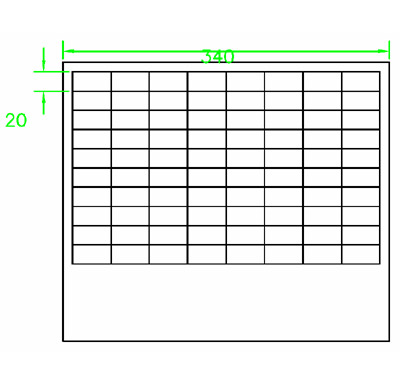

| Die Layout |  |

| Cutparts Layout |  |

| Quantity of Cutpart | 160 pieces (material size 340 × 405mm) |

| Material Yielding Rate | 93% |

Specification:

| Model | HS-30 | HS-40 |

|---|---|---|

| Cutting Force | 30 tons | 40 tons |

| Cutting Stroke | 130 mm | 130 mm |

| Open Daylight | 25–155 mm | 25–155 mm |

| Motor | 7.5 Hp | 7.5 Hp |

| Down Speed | 52.9 mm/sec. | 52.9 mm/sec. |

| Up Speed | 101.7 mm/sec. | 101.7 mm/sec. |

| Capacity | Up to 40000 cuts per 8 hours depending on processing | |

| Cutting Head | 500*500 / 650*650 mm | 500*500 / 650*650 mm |

| Dimension | 1730L*1480W*2000H mm | 1730L*1480W*2000H mm |

| Weight | 3300 KG | 3400 KG |

◎The above are the basic standard specifications. Special specifications are available upon request.

◎Dimensions and weights are for main machine body only without feeder.

◎Open daylight is measured from beam to bed, effective open daylight need to deduct thickness of die, cutting pad and feeder.