2001

Chinup was established in Tainan, Taiwan.

Started to provide equipment for Optoelectronics Industry

2002

Technological cooperation with Freeman Schwabe® Machinery ,located in Ohio, USA, to develop large automotive interior cutting machine.

2003

Phase 1 of factory expansion- located in Tainan Technology Industrial Park.

2004

Signed exclusive distribution agreement for European region with Hawkes Technical Ltd.

Develop tape laying machine for optoelectronics industry develop labeling machine.

Attended K2004 exhibition.

2006

Phase 2 of factory expansion- located in Tainan Technology Industrial Park.Manufacturing plant occupied a total area of 10,000 square meters.

Was approved to join“the developing and manufacturing plan of solar module laminator” under SBIR project leaded by Department of Industrial Technology, Ministry of Economic Affairs, that was to encourage small and medium enterprises to develop new technologies.

Exported the first sand screenmat cutting machine with self-developed nesting software.

2007

Established new production line to develop automated manufacturing equipment for solar module.

➀ Launched he first self-developed solar cell module production line in Taiwan.

➁ Invested and establishedANJI technology Co., Ltd.

Attended K2007 exhibition with Hawkes Technical Ltd.

Headquarters relocated to Tainan Technology Industrial Park.

2009

Exported 20MW solar module production line to India.

2010

Imported CCD alignment cutting system.

Exported the first powder puff cutting machine.

2012

Exported the first floor tile cutting and automatic stacking machine.

2013

Exported the second 20MW solar module production line to India.

2014

Delivered the first 120 inch optical film cutting machine.

Established Suzhou Chinup( China) Trade Co., Ltd, the service base in China.

Invested in solar power stations- Chiayi region

2015

Invested in solar power stations- Tainan region

Invested in solar power stations- New Taipei region

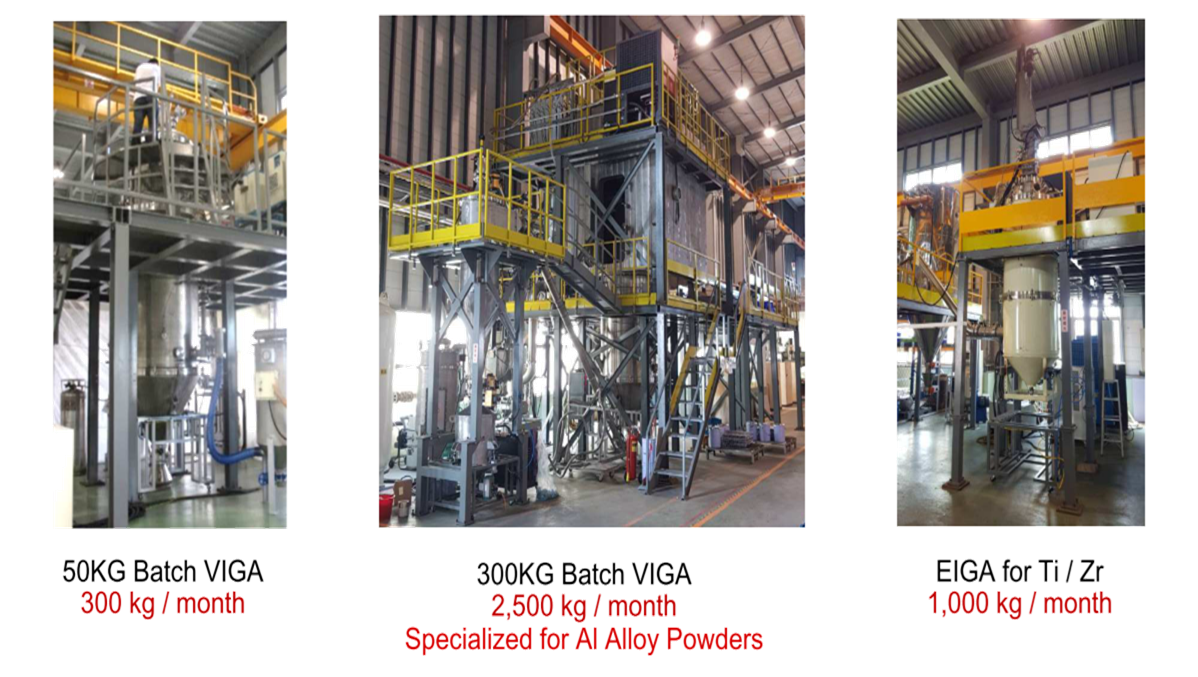

Cooperated with National Cheng Kung University to invest in industry-academia cooperative value creation project- “Gas atomization equipment to produce metal powder for additive manufacturing ” that was promoted by Ministry of Economic Affairs.

2016

Launched servo hydraulic energy saving system.

Invested and establishedCircle Metal Powder Co., Ltd.that is specialized in high quality metal powder for additive manufacturing.

2019

Developed polarizer cutting machine that is used in optoelectronic industry.

2021

Launched the first electric cutting machine.

2023

Cooperated with ANJI technology Co., Ltd. and National Formosa University to develop the project of“Coaxial-rotors unmanned aerial vehicle ” .

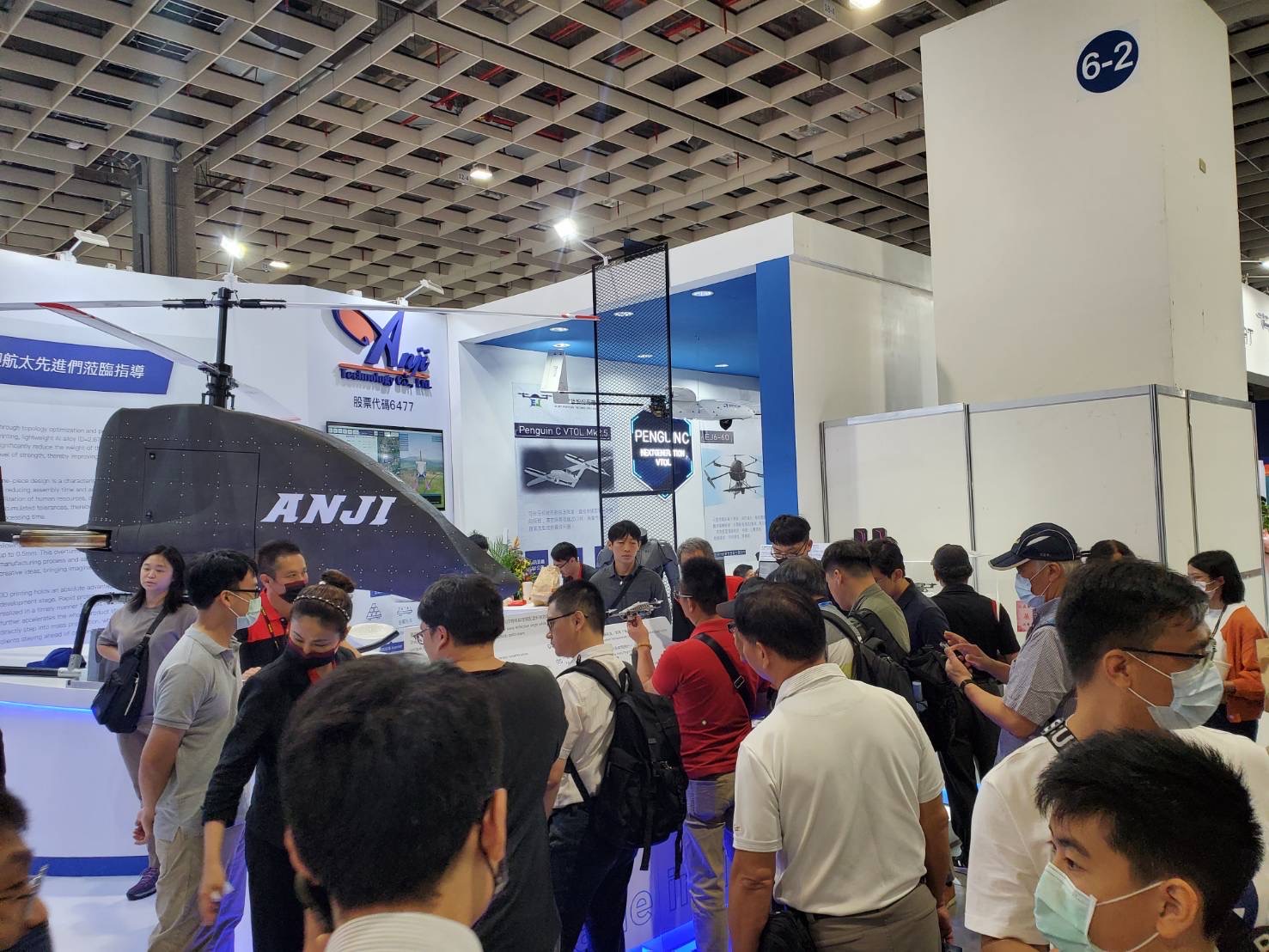

Attended 2023 Taipei Aerospace & Defense Technology Exhibition with ANJI technology Co., Ltd. exhibiting 3D-printed drones.

2024

Built the first additive manufacturing machine (3D printer).